Foreign Insulators

by Marilyn Albers

Reprinted from "Crown Jewels of the Wire", June 1994, page 17

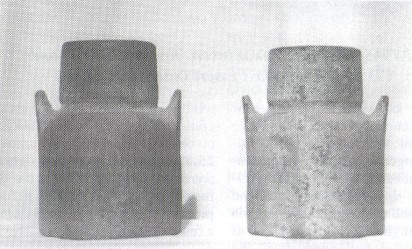

THE "IRON MEN"

This pair of insulators are aptly nicknamed the "Iron Men", because

the outer shells are made of cast iron, and they closely resemble the French

style we refer to as the "gingerbread man". At first glance, you'll

think they are identical, so why the different classification numbers? The

reason for this is that the insulator on the left has a porcelain inner skirt

and that on the right has one of green glass! Both inserts are held in place

with cement. Now just where would you put them in the foreign style charts?

Would you put them there at all? This is sort of like catching two fish, one

covered with feathers and the other with fur, but they are still fish!

The "Iron Men" U-1965B (left) and CD 649 (right)

Jack

Tod had a solution. When he and I were putting together the 1986 Supplement of

Worldwide Porcelain Insulators and scale drawings were being made of new styles,

there were several insulators. with iron shells and porcelain inner skirts

included in the well known Keith Neal collection (Guernsey, Channel Islands).

Even though they were a mixture of materials, Jack hated to leave them out of

the U-Chart because of their rarity and their definite place in the

history of worldwide insulator manufacturing. So he made a space for them and

the unmarked ironclad gingerbread man with porcelain inner skirt was classified

as U-1965B. In 1981, a family friend had found this insulator in Tunisia and

brought it back as a gift. It was the only I had seen until the Metroplex show

in Grapevine, Texas, March 26th of this year. Amazing insulators have turned up

at this annual show!

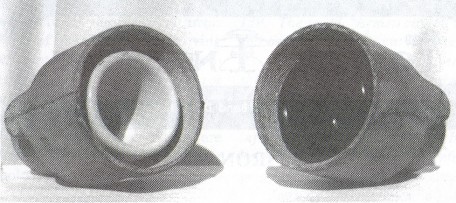

U-1965B with porcelain insert inner skirt (left) and

CD 649 with a glass

insert inner skirt (right)

As I was setting out my sales stock that day, a collector

asked me if I had seen the foreign insulators on Ron Haglund's table. A fast trip

around the corner put me in front of three large gingerbread men, including one

unmarked white porcelain (U-2057) and two of glass (CD 642) with familiar French

embossings. The fourth piece was an ironclad gingerbread man! Just finding

another of these was exciting, but when I turned it over my heart skipped a

beat. The inner skirt was made of green glass! It was fairly dirty, but I took

it to the window and reading backwards I could make out the word ISOREX on one half-mold

and the numbers 25.41 on the opposite half. There were no other markings on the

insulator. Ron told me that all four pieces had come out of Tunisia just a few

days before the show. Three of them were definitely of French manufacture, which

tells us that Tunisia probably relied heavily on imported insulators for local

use, if indeed there were any insulator factories in this country at all. The

glass insert of the iron clad piece was made before 1959 by a manufacturer in

the city of Reims called Nord-Verre. "ISOREX" was the official

company trademark used on glass insulators. Quite possibly "41 " is

the date of manufacture, but there is no way to be sure. Siemens Brothers &

Co., Ltd. of London may have supplied the cast iron shells for both of the Iron

Men, since their 1910 catalog offered several styles of "Iron Hooded"

insulators.

It was a little harder to convince Woody that this insulator needed a CD number. He was diametrically

opposed to including it in a CD Style Chart of glass insulators and this is

certainly understandable. But since the precedent had already been set by Jack's

saving a place in the Universal Style Chart for ironclad insulators with

porcelain inner skirts, Woody finally agreed to classify this new find as CD

649, but he is still shaking his head.

THE "P.M.G." INSULATOR

CD 121 "P.M.G."

CD 121 is not an uncommon insulator style, but I seriously doubt if any of

you have seen one embossed "P.M.G" (Post Master General). I have not

actually seen

this piece either, but when husband Bill and I made our trip to Australia in

the fall of '93, we had a good visit with Brian Woodman, a collector from Corio,

Victoria (See February 1994 issue of Crown Jewels). He has definitely seen this

insulator, and though he doesn't own it, he would like to, and all his fingers

and toes are crossed. The owner is very protective of it, but did allow Brian to

take a photo, which in turn was sent to me along with the negative. The

"P.M.G." is an extremely rare piece in that it is one of only six

known to have survived, all of which are of the same light blue glass. These six

are loved and treasured by relatives of the man whose company produced a limited

number of them sometime between 1912 and 1915, the four years the factory was in

operation. Thanks to Brian, we do have some historical information on this

insulator, though he has not told me the exact source. The material is rather

extensive, so I have condensed much of it, but in order to avoid losing some of

the flavor, two sections are quoted directly. These you will find in italics.

Edward L.R. Roberts was born in England in 1864. He was the oldest son of the

late Mr. Edward Robert of Kent, England, a distinguished English astronomer who

was decorated by King Edward VII for his work in connection with the invention

of a "time-predicting machine", used extensively by the government of

the day. His mother was a member of the well-known family of Wedgewood, who were famous potters, and one of his aunts

was married to the eminent scientist, Charles Darwin. Edward the younger

studied medicine for a time, but soon gave that up to train as an industrial

chemist and became involved in the manufacture of glass in Scotland and England.

He followed a family tradition, as several generations before him had been

glassmakers.

Edward came to Australia in 1889 at the age of

twenty-five. He opened

a business on Flinders Street in Melbourne and was employed by a number of firms

interested in the manufacture of glass. There he fell in love with his first

cousin Jessie Alger, whom he first met when she visited England at age sixteen.

They' were married in 1891 and for several years Melbourne was their home. Part

of that time, Edward was employed by Brooks Robinson, well known makers of

stained glass, who were responsible for many beautiful Church windows.

The

family eventually moved to Lake Tyers where Edward managed the Lake Tyers

"Guest House". In 1902, at age 31, Jessie Roberts died, leaving her

husband with three sons, Gilbert (age 8), Herbert (age 6), Stanley (age 4) and a

daughter Jessie (age 1). Edward took the children and went back to England.

After two years there, they returned to Lake Tyers, a place they had all come to

love. In 1908 Edward was married a second time, this time to Emma Curtis, by

whom he had one son, John Arthur, born in 1916.

About the time of his second

marriage, Edward received a large sum of money from his father and established a glassworks on the shores of

Lake Tyers. This project was described by his son Gilbert:

"My father built the glass factory at Lake Tyers during 1908 and 1909.

(Father had previously owned a glass factory in England.) The P.M.G. had

advertised for glass insulators and father applied for the contract. The glass

factory itself was 150' wide by 300' long and had a 25' lean-to on the eastern

side. The First section was the engineering shop for fitting and turning (where

I mainly worked), the second section was the blacksmith shop and the third

section was the batch room. It had an open hearth furnace and father said there

were only three in the world (the others being in Belgium and England). The

other two used gas, but we used wood. We had to achieve 12,000 to 14,000 degrees

Celsius white heat. The usual South Yarra bricks could not withstand this heat,

so we used bricks from Bacchus Marsh. We did not use beach sand, but the inside

wash sand, a quartz sand collected from our property. The P.M.G. gave us only a

blueprint, so we made our own moulds (made in four pieces), the presses and

stands and the wooden patterns for the castings. We made everything needed for

the manufacture of glass right on the property, and also did all our own machine

work there on the premises.

We made a few other things such as glass money boxes and preserving jars in 1-1/4, 1-1/2 and 1 lb.

sizes. We also made silicate of soda for preserving eggs."

Roberts, being a clever inventor, solved a difficult technical problem by

figuring out how to make an internal screw in telegraph insulators. He

contracted to supply 100,000 of these CD 121 's, half of which were for New

South Wales and half for Victoria. He employed 13 men at the factory, as well as

a few Aborigines who came across the lake to work there. When the lake was

closed, the glass products were taken to Lakes Entrance by bullock dray. When it

was open, they were transported by boat to Cross's Landing and from there to

Lakes Entrance by road. At Lakes Entrance they were transferred to steamships

and taken to Bairnsdale to be loaded on the train to Melbourne.

"Production of insulators at Lake Tyers ceased soon after the outbreak of the First World War. Although the factory continued to operate

for a short time, producing twisted walking sticks, bottles and jars of green

glass, it was forced to close in 1915. One informant believes that the contract

was not renewed because it was no longer possible to import soda ash from

Germany and competitors cornered the local supplies. There were also reports

that a P.M.G. inspector was not satisfied with the quality of all the

insulators. The unexpected failure of this ambitious project must have been a

severe blow to Edward Roberts. There seems to be no doubt that he had a thorough

knowledge of glassmaking, but he may have underestimated the need for skilled

workers to assist him with the enterprise."

Many thanks to Brian Woodman for supplying this information. It is a welcome

and valuable contribution to the insulator collecting hobby.

|